Our vision

redefining hand protection

The human hand is, and always has been a precious tool we all know, and use every day. Today, our hands are exposed to the same risks as they were before (burns, frostbite, cuts, irritations, etc.), in addition to a number of musculoskeletal disorders. For today, it is the environment within which the hand is used that has changed. Users work in increasingly complex environments with new and cross risks.

Our vision consists in continuously providing the ultimate solution for users faced with a perpetually changing environment. By placing the end user at the heart of our R&D, Wonder Grip’s range of solutions evolves on a permanent basis, redefining the very notion of hand protection.

Our values

WE DEMAND qualitY

From the choice of raw materials to the final product,

Wonder Grip commands and controls all production process phases.

After painstakingly selecting the raw materials used to produce our gloves, Wonder Grip permanently controls each and every step of the production process. Thanks to our implemented quality management system, Wonder Grip examines the quality of its products, at varying stages, on a daily basis.

UnRIVALLED comfort

Resulting from several years of research and development, Wonder Grip has developed ergonomic moulds aimed at offering its users maximum comfort.

Whatever the working conditions, we believe that, over and above protection, it is essential to offer optimal comfort to all users. As such, our engineer teams have developed ergonomic moulds that perfectly match the natural shape of a hand at rest. Hence, each of our product references aims at considerably reducing muscular fatigue, at preventing musculoskeletal disorders (MSDs), whilst offering security, whatever the working environment.

innovation to serve performance

In response to technical changes and changes in working conditions,

Wonder Grip places innovation at the heart of its daily activities.

Our engineers innovate every day to offer our users ever-increasingly innovative products. They do so, in particular, through continuous product improvement and via the development of new technical fibres. Wonder Grip calls upon a panel of experts and end users to develop and validate the performance of its new products. What’s more, we apply the same degree of top-level requirements to the attractiveness and the modernity of our product design, in an aim to equally satisfy aesthetic demands.

Wonder Grip production plants at the foreFront of certification

Over and above offering innovative solutions,,

Wonder Grip is committed to adopting an all-embracing environmentally friendly approach.

From its very creation, Wonder Grip implemented a health, safety and environment quality management system (HSEQ) This system has enabled us to obtain triple certification based on the requirements set forth in the ISO 9001, ISO 14001 and ISO 45001 (ex OHSAS 18001) standards. Wonder Grip is also renowned for:

- top quality products

- respect for the environment

- the health, safety and well-being of its employees

All our gloves are OEKO-TEX® certified. In accordance with REACH regulations, we guarantee that all our products are and will remain devoid of any ‘Substances of Very High Concern’ (SVHC).

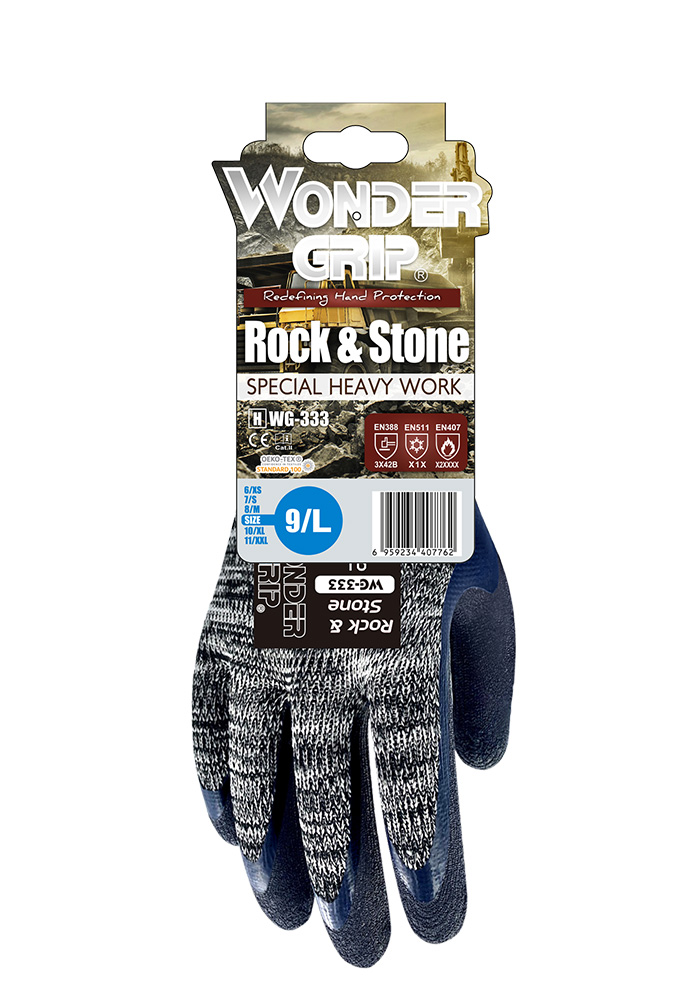

Retail experts

Wonder Grip has a strong reputation in the international retail segment. We offer a varied range of displays that are easy to implement. All our products are available in blister format so they can be hung from displays.

CHOOSE YOUR SIZE

CHOOSE YOUR PROTECTION

Our displays are accompanied by an explanatory sheet to guide consumers in choosing their protection.

An international company

Wonder Grip is present across the globe. Our parent company is based in Tokyo, Japan.

As close relationships to customers are a core priority, Wonder Grip has established plants in Europe:

- Wonder Grip Europe B.V. based in Amsterdam, in the Netherlands

- Wonder Grip UK Ltd based in Manchester, in the United Kingdom

- Wonder Grip Germany based in Hannovre, in Germany

Wonder Grip is also established in the United States.

We rely on expertise from our logistics partners to offer reactive, flexible and transparent service.

Wonder Grip is in

North America

- The United States

South America

- Brazil

- Equator

- Peru

Asia

- China

- Indonesia

- Japan

- Philippines

- Thailand

- Vietnam

Africa

- Morocco

- South Africa

europe

- Germany

- Belgium

- Croatia

- Denmark

- Spain

- Estonia

- Finland

- France

- Hungary

- Ireland

- Iceland

- Italy

- Luxembourg

- Norway

- Netherlands

- Poland

- Portugal

- United Kingdom

- Slovakia

- Slovenia

- Sweden

- Switzerland

- Turkey